Table of Contents

Businesses are increasingly leveraging AI to optimize the flow of goods—from sourcing raw materials to manufacturing and final delivery—helping them enhance efficiency and reduce operational complexities. Supply chain management (SCM) involves multiple teams, including procurement, quality assurance, and production, all working together to ensure smooth operations.

However, traditional SCM methods often struggle to keep pace with fluctuating demand, logistical challenges, and inventory management inefficiencies.

With the growing availability of AI-powered supply chain solutions, businesses of all sizes now have access to advanced tools that streamline processes, automate repetitive tasks, and provide deeper insights into supply chain data. AI is transforming SCM by improving efficiency, enhancing accuracy, and enabling data-driven decision-making. This article explores the impact of AI in supply chain management and how companies can harness its potential to optimize operations.

How does AI work in supply chain management?

Artificial Intelligence (AI) is transforming AI in supply chain management (SCM) by automating processes, analyzing vast amounts of data, and optimizing decision-making. AI-powered technologies improve efficiency, reduce costs, and enhance accuracy across various supply chain functions, from demand forecasting to last-mile delivery.

Key AI Applications in Supply Chain Management

Machine Learning (ML) for Demand Forecasting – AI analyzes historical data, market trends, and external factors to predict demand fluctuations, optimizing inventory management and minimizing waste.

- Robotic Process Automation (RPA) – AI automates repetitive tasks such as order processing, invoice management, and data entry, improving operational efficiency and reducing human errors.

- Natural Language Processing (NLP) for Customer Support – AI-powered chatbots and virtual assistants enhance communication, provide real-time tracking updates, and handle customer queries efficiently.

- Computer Vision for Quality Control – AI-driven visual inspection systems detect defects in products and packaging, improving quality assurance and minimizing production errors.

- Data Collection & Analysis – AI gathers real-time data from IoT sensors, sales records, weather forecasts, and supply chain trends to provide actionable insights and enhance decision-making.

- Inventory & Warehouse Optimization – AI-powered systems track stock levels, prevent overstocking or stockouts, and automate warehouse management using robotics and smart sensors.

- Logistics & Route Optimization – AI analyzes traffic patterns, weather conditions, and delivery schedules to optimize transportation routes, reducing fuel consumption and improving on-time deliveries.

- Supplier & Risk Management – AI evaluates supplier reliability, monitors geopolitical risks, and detects potential disruptions to build a more resilient supply chain.

By integrating AI into SCM, businesses can enhance agility, minimize risks, and create a more responsive, data-driven supply network. AI not only streamlines operations but also strengthens supply chain resilience, ensuring businesses stay competitive in a rapidly evolving market.

Top 5 Benefits of AI in Supply Chain Management

Implementing AI in supply chain management (SCM) provides significant advantages, improving efficiency, reducing costs, and enhancing decision-making. Beyond operational improvements, AI also strengthens risk management, compliance, and competitiveness. Here are five key benefits:

- Enhanced Efficiency & Automation – AI automates routine tasks such as inventory tracking, demand forecasting, and order processing, reducing human errors and increasing productivity. This leads to faster, more efficient operations.

- Improved Demand Forecasting – Machine learning algorithms analyze historical data and market trends to predict demand more accurately. This helps businesses optimize inventory levels, minimize stockouts, and reduce excess inventory costs.

- Optimized Logistics & Transportation – AI-powered route optimization and predictive analytics improve delivery schedules, reduce fuel consumption, and lower transportation costs, leading to more reliable and cost-effective logistics.

- Better Risk Management & Compliance – AI detects potential disruptions, such as supplier failures or geopolitical risks, allowing businesses to take proactive measures. It also ensures regulatory compliance by monitoring changing requirements.

- Stronger Supplier & Customer Relationships – AI-driven insights help businesses assess supplier reliability and customer preferences, leading to improved collaboration, better service, and stronger long-term partnerships.

By leveraging AI, businesses can build smarter, more resilient supply chains, gaining a competitive edge in an increasingly complex market.

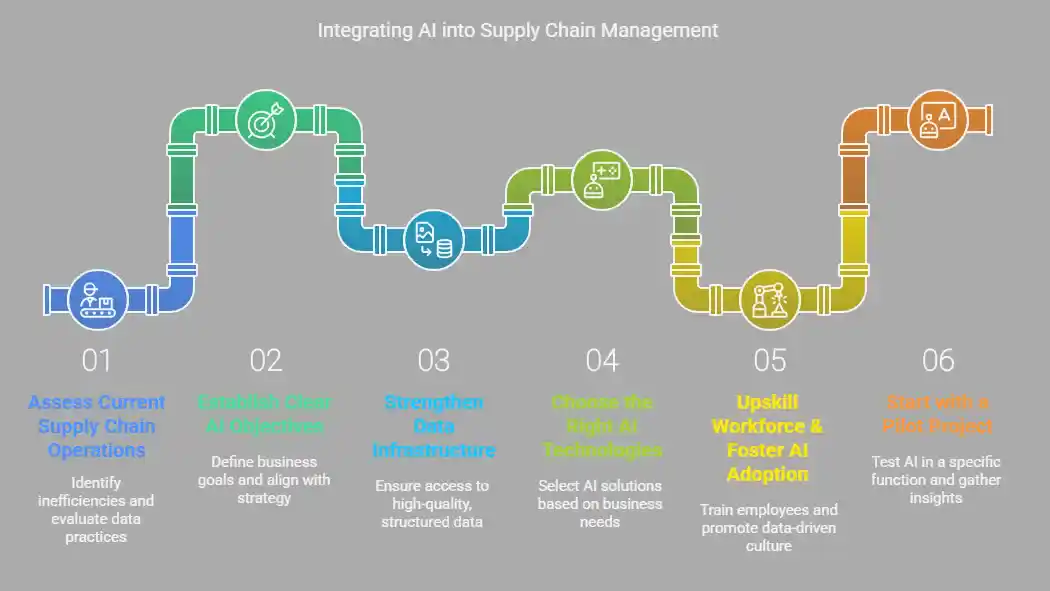

Steps to Prepare a Supply Chain Management for AI

Implementing AI in supply chain management (SCM) requires careful planning and execution. Here are the key steps to prepare your supply chain for AI integration:

1. Assess Current Supply Chain Operations

- Identify inefficiencies, bottlenecks, and areas where AI can provide value.

- Evaluate existing data collection, storage, and management practices.

2. Establish Clear AI Objectives

- Define business goals, such as improving demand forecasting, optimizing logistics, or reducing costs.

- Align AI implementation with overall supply chain strategy.

3. Strengthen Data Infrastructure

- Ensure access to high-quality, structured data from multiple sources (IoT, ERP, CRM, etc.).

- Invest in data integration tools and cloud-based storage for scalability.

4. Choose the Right AI Technologies

- Select AI solutions such as machine learning, robotic process automation, and predictive analytics based on business needs.

- Evaluate AI vendors and platforms for compatibility with existing systems.

5. Upskill Workforce & Foster AI Adoption

- Train employees on AI-driven tools and workflows.

- Promote a data-driven culture and encourage collaboration between AI and human decision-makers.

6. Start with a Pilot Project

- Test AI in a specific supply chain function, such as inventory management or route optimization.

- Measure performance, gather insights, and refine AI models before full-scale implementation.

7. Ensure Security & Compliance

- Implement robust cybersecurity measures to protect supply chain data.

- Ensure compliance with data protection regulations (GDPR, CCPA, etc.).

8. Scale & Continuously Optimize

- Gradually expand AI applications across the supply chain.

- Continuously monitor AI performance, refine algorithms, and adapt to evolving business needs.

By following these steps, businesses can successfully integrate AI into their supply chains, improving efficiency, resilience, and competitiveness.

Challenges of Implementing AI in Supply Chain Management

Despite its benefits, integrating AI into supply chain management (SCM) presents several challenges:

- High Initial Investment – AI adoption requires significant investment in technology, infrastructure, and skilled personnel. Businesses must allocate funds for AI software, cloud storage, and data analytics, which can be costly, especially for small and medium-sized enterprises (SMEs).

- Data Privacy & Security Risks – AI systems handle vast amounts of sensitive supply chain data, increasing cybersecurity risks. Companies must implement strong encryption, access controls, and compliance with regulations (e.g., GDPR, CCPA) to safeguard information.

- Change Management & Workforce Adaptation – AI implementation demands process re-engineering and workforce upskilling. Employees may resist AI adoption due to concerns about job displacement. Businesses must focus on training and fostering collaboration between AI and human expertise.

Addressing these challenges strategically can help businesses maximize AI’s potential while ensuring a smooth transition to a smarter, more efficient supply chain

How AI in Supply Chain Management Enhances Sustainability

AI plays a crucial role in making supply chains more sustainable by optimizing resource use, reducing waste, and lowering carbon footprints. Here’s how AI contributes to sustainability in supply chain management:

- Optimized Inventory & Waste Reduction – AI-driven demand forecasting helps prevent overproduction and excess inventory, reducing waste and unnecessary resource consumption. This minimizes landfill contributions and promotes a more sustainable supply chain.

- Energy Efficiency in Logistics – AI-powered route optimization reduces fuel consumption by identifying the most efficient delivery paths, decreasing carbon emissions from transportation. AI also enables smart fleet management, promoting eco-friendly shipping solutions.

- Sustainable Sourcing & Supplier Monitoring – AI evaluates suppliers’ sustainability practices, ensuring that businesses source materials ethically and from environmentally responsible vendors. This strategic sourcing also helps monitor ESG (Environmental, Social, and Governance) compliance.

- Smart Manufacturing & Resource Optimization – AI-driven predictive maintenance and real-time monitoring improve equipment efficiency, reducing energy consumption, water usage, and material waste in production.

- Circular Economy Support – AI enables better recycling, reuse, and remanufacturing strategies by identifying opportunities to extend product life cycles and reduce dependency on virgin raw materials.

By integrating AI into supply chain operations, businesses can significantly improve sustainability, reduce environmental impact, and meet global green initiatives while maintaining efficiency and profitability.

Future Trends of AI in Supply Chain Management

AI is set to revolutionize AI in supply chain management (SCM) by making operations smarter, more efficient, and sustainable. Here are three key future trends shaping the industry:

- Autonomous Supply Chains – AI-driven supply chains will become increasingly autonomous, using self-learning algorithms to optimize processes with minimal human intervention. Advanced robotics, predictive analytics, and AI-powered decision-making will streamline procurement, inventory management, and logistics, reducing delays and improving efficiency.

- Blockchain & AI Integration – The combination of blockchain and AI will enhance transparency, security, and trust in supply chains. AI can analyze blockchain-recorded transactions to detect fraud, optimize contract execution, and improve traceability of goods. This integration ensures real-time visibility, reducing risks related to counterfeit products and supply chain disruptions.

- AI-Powered Sustainability Initiatives – AI will play a crucial role in making supply chains more sustainable by optimizing energy use, reducing waste, and improving resource allocation. AI-driven predictive maintenance minimizes equipment downtime and energy consumption, while smart logistics solutions reduce carbon emissions by optimizing transportation routes and load distribution.

As AI technology continues to evolve, supply chains will become more resilient, adaptive, and environmentally conscious, driving long-term business success.

Conclusion

AI in supply chain management by enhancing efficiency, accuracy, and sustainability. From demand forecasting and logistics optimization to risk management and sustainability initiatives, AI-powered solutions enable businesses to streamline operations, reduce costs, and improve decision-making. While challenges such as high initial investment and workforce adaptation exist, strategic implementation and continuous optimization can unlock AI’s full potential.

As AI technology advances, supply chains will become more autonomous, resilient, and transparent, helping businesses stay competitive in a rapidly evolving global market. By embracing AI-driven innovations, companies can not only enhance operational efficiency but also contribute to a more sustainable and intelligent supply chain ecosystem.

FAQ

What is AI in supply chain management?

AI in supply chain management refers to the use of artificial intelligence technologies such as machine learning, robotic process automation, and predictive analytics to optimize logistics, inventory management, demand forecasting, and overall supply chain operations.

How does AI improve efficiency in supply chain management?

AI automates repetitive tasks, enhances demand forecasting, optimizes logistics routes, streamlines warehouse operations, and improves decision-making, leading to increased efficiency and reduced operational costs.

What are the main applications of AI in supply chains?

AI is used for demand forecasting, inventory management, logistics and route optimization, supplier risk assessment, quality control, and customer support through chatbots and automation.

What are the challenges of implementing AI in supply chain management?

Key challenges include high initial investment, data privacy and security risks, integration with existing systems, workforce adaptation, and resistance to change.

Can small businesses benefit from AI in supply chain management?

Yes, AI-powered supply chain solutions are becoming more accessible, allowing small businesses to optimize inventory, automate tasks, and improve customer service without requiring massive investments.