Table of Contents

The impact of AI on construction safety is undeniable. Construction sites are chaotic by nature. Heavy machinery, heights, electrical wiring, and vehicles: these moving parts will expose workers to heightened risks day in and day out. The numbers don’t lie: according to the U.S. Occupational Safety and Health Administration (OSHA) in 2022, the construction industry, which accounts for about 7% of the U.S. workforce, accounted for 21.1% of workplace fatalities. And what causes most of these hazards?

The “Fatal Four”: falls, struck by, electrocution, and caught in/between accidents – account for 60% of construction deaths. Classic safety measures are vital (helmets and vests, we see you), but they are reactive and not proactive. They don’t scale. They don’t anticipate. And that’s where artificial intelligence (AI) comes in to rewrite that narrative.

Besides safety, AI is proving transformative in streamlining construction workflows. HyScaler, for example, has developed a range of AI-powered solutions meant to keep projects on track and protect workers simultaneously. Included are advanced tracking and observation systems that report on the real-time movement of workers, equipped with built-in offline work reporting to ensure that even remote sites stay connected. This makes it easy for managers to maintain oversight, while timeline tracking based on task completion helps avoid delays and ensure adherence to project schedules.

Want the real kicker? According to McKinsey, AI-based predictive tools can cut construction site accidents by up to 30%. That’s right, a combination of AI-powered wearables, camera surveillance, and predictive modeling means spotting the hazards before they even happen.

How the Impact of AI on Construction Safety is Redefining Risk Management

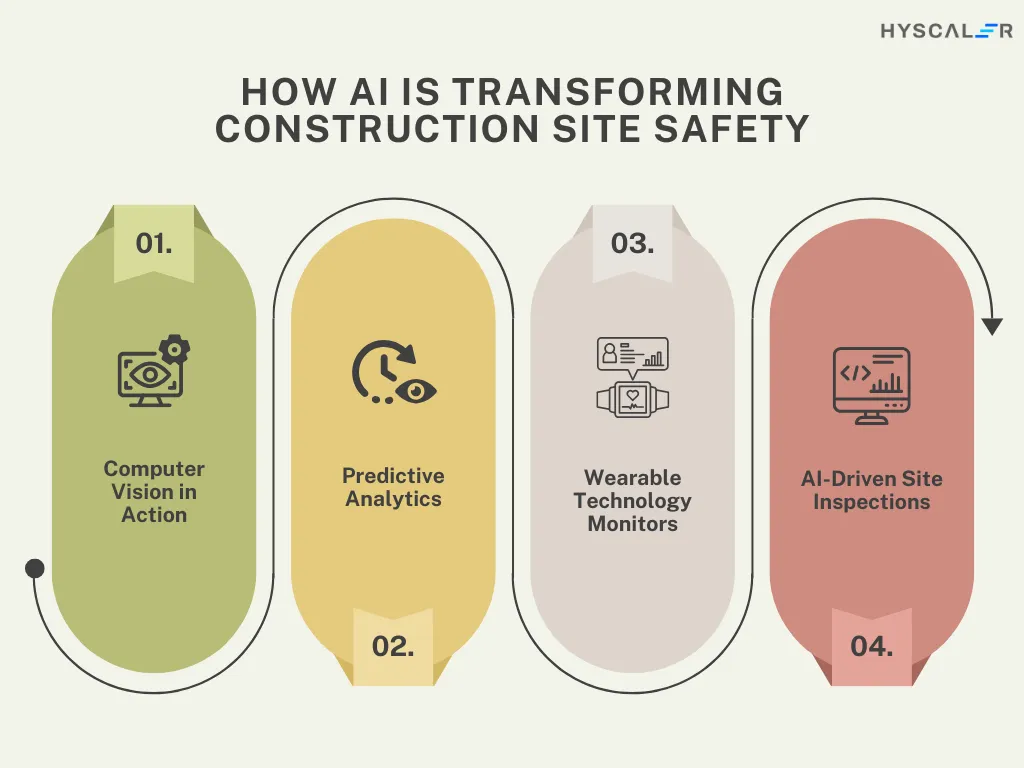

AI technologies, including computer vision, machine learning, and the Internet of Things (IoT), enable a shift from reactive to predictive and preventative safety management in construction. Here’s the power of AI:

1. Computer Vision in Action: Real-Time Hazard Detection for Enhanced Safety

Computer vision can stream real-time data from your construction site via cameras, detect unsafe behaviors (like a worker forgetting their harness at height), and immediately send alerts.

Case in point: Imagine a worker slips, or wears their PPE incorrectly — AI sends out warnings and allows supervisors to step in instantly. It’s the safety supervisor who never sleeps.

Source: According to the Boston Consulting Group (BCG), companies that have implemented AI-based hazard detection saw a 25% increase in response time, drastically improving accident prevention.

2. Predictive Analytics: A New Frontier in Risk Anticipation

Work smarter, not harder. AI uses historical data to find patterns that are linked to accidents maybe in severe weather combined with roofing work spikes danger. Possibly, human fatigue sets in at specific work hours. Armed with this data, site managers can adjust schedules or allocate more safety resources during high-risk times. A storm’s on its way? Shift high-risk activities off the schedule or intensify supervision. Prevent, don’t react.

Case in point: In the case of heavy rainfall, predictive analytics calculates the possibility of machine-caused accidents on damp surfaces. The system alerts workers to be ready or halt operations expecting an incident.

Source: According to Deloitte’s analysis, the accident statistics are reduced by up to 25% using predictive techniques. It ensures that readiness is always facilitated.

3. Wearable Technology Monitors: A New Era of Worker Safety

It’s not sci-fi anymore. Smart helmets, vests, and gloves that can track worker stats in real-time are here. AI-enhanced wearables monitor a worker’s heart rate, temperature, and even fatigue levels to prevent accidents caused by physical exhaustion or exposure to dangerous elements.

Case in point: A worker starts sweating excessively during warm weather. Their smart vest picks it up, and AI sends a command for an immediate break. This real-time monitoring ensures that workers don’t overpush themselves into dangerous situations.

Source: According to Deloitte, implementing AI-powered wearables helped construction companies experience an increase in productivity by 20%, precisely because workers were less fatigued, and supervisors made timely interventions.

4. AI-Driven Site Inspections: Compliance at Super Speed

Inspections — we know they’re critical, but they also eat up a ton of time. Here’s where AI-powered drones take the lead. Equipped with thermal sensors and video recording, these drones can autonomously scan the entire worksite searching for safety violations or structural issues, cutting human inspection times by up to 25%.

Case in point: An AI drone conducts a routine inspection at a large construction site, identifying a scaffold that isn’t compliant with safety standards. The system immediately notifies supervisors to take corrective action, ensuring continuous compliance and preventing costly delays.

Source: According to PwC, companies implementing AI-enhanced drone inspections saw inspection times cut by 25%, which in turn significantly improved safety compliance.

Benefits of AI in Construction Site Safety

1. Reduction in Accident Rates

As we stated earlier, McKinsey’s findings show a 30% decrease in onsite accidents when AI is implemented. With tools continuously analyzing risk, AI shifts the narrative: from responding to preventing mistakes before they happen.

2. Improved Efficiency and Productivity

Efficiency. Efficiency. Efficiency.

Safer sites = More productive sites. It’s that simple.

Deloitte’s research shows that with AI tech handling inspections and real-time hazard detection, construction sites experience a 20% boost in overall productivity.

3. Cost Savings on Safety-Related Expenses

Cost Saving: The Hidden Costs Eliminated

The National Safety Council (NSC) estimates the average injured worker will cost almost $42,000 in medical bills plus lost time. AI can cut down on inherent risks that cut down on costly shutdowns, expensive medical bills, & penalties due to missed compliance.

But there is a gem: automated AI inspections have led to 15% cuts in total health and safety-related costs.

4. Enhanced Compliance and Accountability

AI systems digitize safety records and provide detailed logs from site inspections to PPE violations. With everything documented, regulators love it. Audit prep time? Reduced by 25%.

AI decreases the burden of compliance paperwork, increases accountability, and helps pass audits.

Source: Research from the Boston Consulting Group shows that companies using AI for compliance have reduced safety documentation and audit prep by up to 25%.

Challenges and Considerations for Implementing AI in Construction Safety

Implementing AI in construction safety offers promising benefits but has challenges and considerations that organizations need to discuss and resolve to effectively integrate AI into construction safety. The key obstacles and considerations are as follows:

High Implementation Costs:

The implementation of AI technology typically requires a sizeable upfront investment in equipment (like cameras, sensors, and wearables), software, and training. Smaller companies will face significant fiscal barriers as they undertake to make the kinds of investments required to achieve AI integration in their safety programs. Deloitte estimates report that AI implementation in construction can cost between 1-2% of the total project expenditure, which may greatly impact smaller budgets.

Data Privacy and Security Concerns

Construction site AI might also record massive volumes of data relating to the behavior and movement of workers. In this sense, such data is sensitive, and companies need to protect it from illegal access or even data breaches. The General Data Protection Regulation in the European Union, for instance, has strict guidelines on personal data handling. This substantially makes things harder for AI deployment.

Workforce Adaptability and Training

The construction workers and their managers might not be aware of AI and its associated functionalities, and this is a concern in terms of adaptability. All the employees should be trained on such new technologies so that they can understand and trust them effectively to implement AI. According to the McKinsey report, 40% of construction firms presently experience difficulties in training employees to use digital tools; hence there is an instance of resistance or failure to utilize AI systems.

Reliability and Accuracy of AI Predictions

Thus, AI systems would rely on good-quality data to make exact predictions. In such an environment of construction where variables change now and then, the accuracy and reliability of the predictions of AI are difficult to ascertain. False alarms or hazards left undetected by sensors can be due to inconsistency in input data and environmental factors. According to the Construction Industry Institute, false alarms caused by AI systems may result in a productivity loss of 15%. Workers may develop an indifferent attitude towards the alarms provided.

Key Metrics for Measuring the Impact of AI on Construction Site Safety

PPE Compliance Rate

AI systems can monitor PPE compliance in real time. A report by the Boston Consulting Group suggests that AI-enabled PPE monitoring improves compliance rates by up to 20% by providing instant alerts for PPE violations (Boston Consulting Group, 2022).

Alert Accuracy Rate

Measures the accuracy of AI-generated alerts in detecting real hazards. The Construction Industry Institute found that this would require attaining an alert accuracy rate of over 90% to reduce false alarms, which in turn helps keep the worker responsiveness levels high to real dangers (Construction Industry Institute, 2023).

Labor Productivity Rate

The usage of AI safety systems generally leads to higher productivity since there are fewer stoppages. As per research done at KPMG, productivity increases between 10-15% in sites using AI since, often, there are fewer interruptions related to safety (KPMG, 2022).

ROI of Implementing AI

Measuring the financial benefit of an investment in AI entails calculating ROI. On average, successful implementations of AI safety in construction show an ROI between 150 and 200 percent within two years, significantly dependent on the lower accident rate and other forms of productivity gains (McKinsey & Company, 2021).

Early Adopters of AI in Construction Site Safety

Purpose:

The timeline will present each company’s gradual integration of AI technologies, the specific tools introduced, and the measurable improvements in safety and efficiency. Each milestone will capture the year, the technology applied, and an impact metric, creating a comprehensive history that demonstrates the value of AI in construction. These insights can also be correlated with advancements in construction estimation software, helping to quantify cost efficiencies gained alongside safety and productivity improvements.

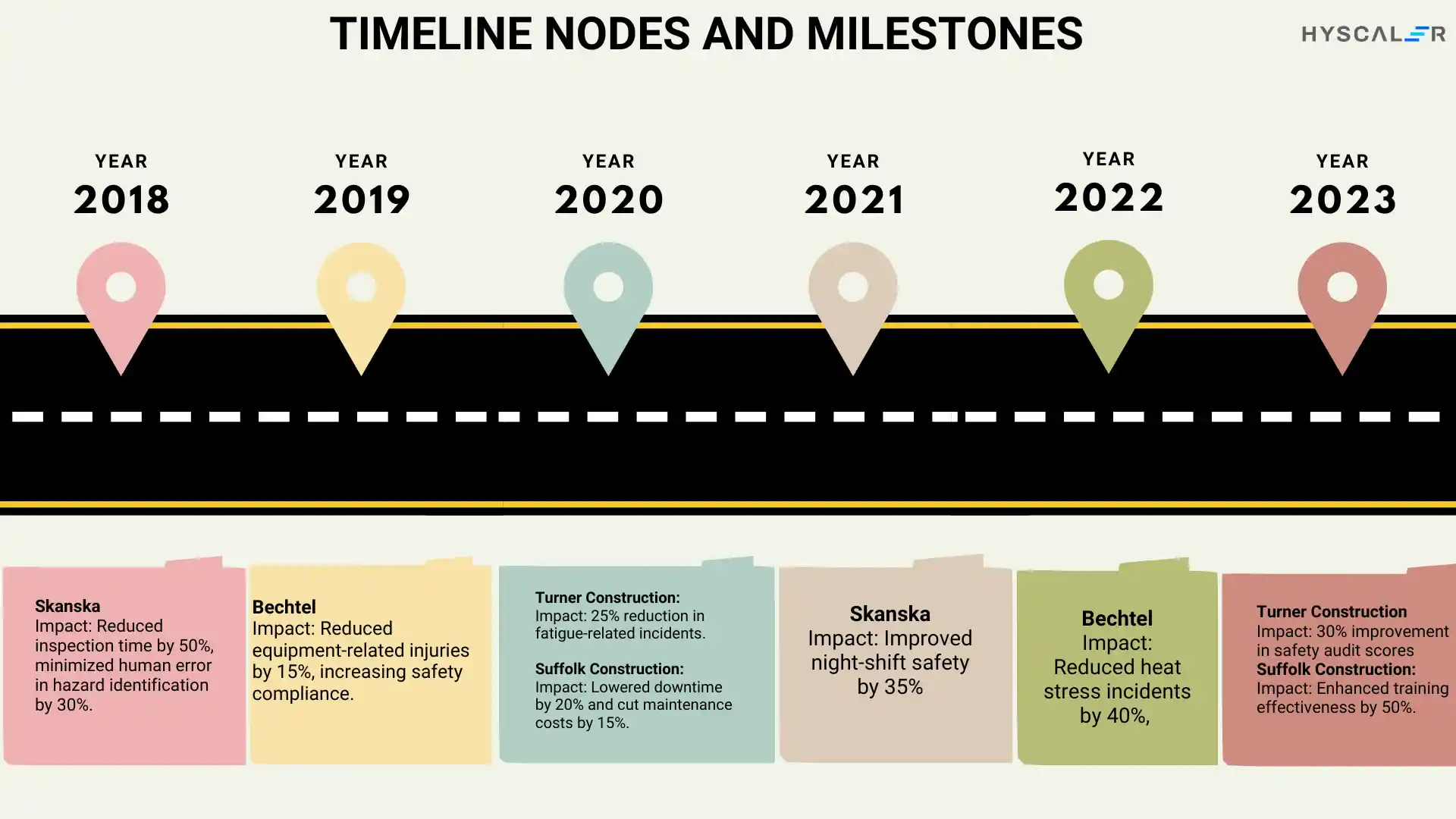

Creating an interactive timeline for early adopter case studies like Skanska, Bechtel, Turner Construction, and Suffolk Construction can indeed provide an engaging view of their AI adoption journey and its impact on safety and productivity. Here’s how we could structure it to ensure it’s visually compelling and informative.

Interactive Timeline: AI Adoption Journey (2018-2023)

Purpose:

The timeline will present each company’s gradual integration of AI technologies, the specific tools introduced, and the measurable improvements in safety and efficiency. Each milestone will capture the year, the technology applied, and an impact metric, creating a comprehensive history that demonstrates the value of AI in construction.

Timeline Nodes and Milestones:

2018

- Skanska:

- Milestone: Skanska begins using AI-powered drones for site inspections.

- Impact: Reduced inspection time by 50%, minimized human error in hazard identification by 30%.

2019

- Bechtel:

- Milestone: Bechtel pilots computer vision for equipment hazard detection.

- Impact: Reduced equipment-related injuries by 15%, increasing safety compliance.

2020

- Turner Construction:

- Milestone: Introduced smart PPE wearables for fatigue monitoring.

- Impact: 25% reduction in fatigue-related incidents; wearables provided data for more efficient break scheduling.

- Suffolk Construction:

- Milestone: Began using predictive analytics to anticipate machinery failures.

- Impact: Lowered downtime by 20% and cut maintenance costs by 15%.

2021

- Skanska:

- Milestone: Expanded AI use with heat-sensing drones for nighttime inspections.

- Impact: Improved night-shift safety by 35% due to accurate hazard identification in low-visibility settings.

2022

- Bechtel:

- Milestone: Deployed wearable technology for real-time health monitoring.

- Impact: Reduced heat stress incidents by 40%, improving overall health outcomes for on-site staff.

2023

- Turner Construction:

- Milestone: Integrated machine learning models to optimize safety protocols.

- Impact: 30% improvement in safety audit scores; machine learning flagged high-risk areas proactively.

- Suffolk Construction:

- Milestone: Utilized AI-assisted training simulations for hazard preparedness.

- Impact: Enhanced training effectiveness by 50%, lowering the accident rate among new hires by 25%.

What’s Next for You?

The evidence is there—implementing AI transforms construction sites into safer, smarter hubs of activity. But it takes investment, training, and a solid plan, especially for organizations looking to escape the perpetual cycle of reactive problem-solving.

The question is simple: Will you adapt and build a safer future with AI, or stay behind?