Table of Contents

Inventory management software reduces operational costs by 15-25% and cuts administrative time by 40-60% within six months of implementation.

This technology automates stock tracking, prevents costly stockouts, and provides data-driven insights that help businesses optimize their inventory levels while improving customer satisfaction.

What Are the Hidden Costs of Poor Inventory Management?

Old-school inventory methods waste time and money.

Workers spend hours updating spreadsheets and counting items by hand.

These manual steps often lead to mistakes and wrong data.

Money Lost from Bad Management

Companies without good systems face these problems:

- Too much stock ties up cash

- Empty shelves mean lost sales

- Rush orders cost more money

- Storage fees grow with extra items

Studies show businesses lose about 8% of yearly sales due to bad inventory control.

The National Retail Federation reports that inventory shrinkage costs U.S. retailers $94.5 billion annually.

North America dominated the global inventory management software market with a major share of over 40% in 2024, showing how crucial proper inventory control has become.

How Automated Systems Save Time

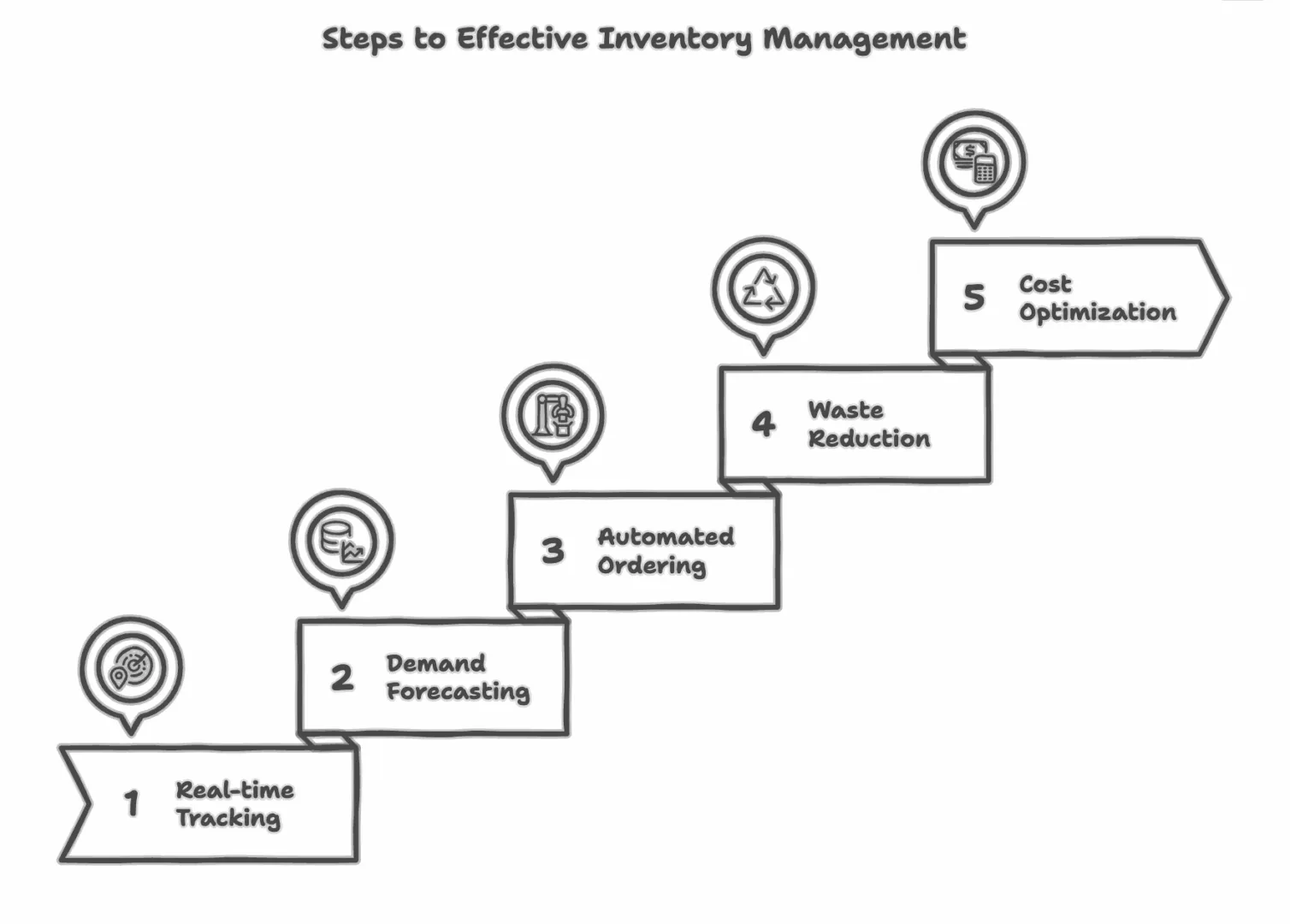

Real-Time Stock Updates

Inventory management software stops the need for manual updates.

The system changes stock numbers as sales happen. This gives you correct inventory data without any work from staff.

Easy Reordering

Auto reorder points prevent empty shelves and cut ordering work.

The software makes purchase orders when stock gets low. This removes the need to watch levels all the time.

Faster Audits

Digital systems make inventory checks quicker and more accurate.

Barcode scanners cut counting time by 75%.

Research from Aberdeen Group shows companies using automated inventory systems achieve 99.7% inventory accuracy compared to 63% for manual systems.

Cutting Costs with Smart Planning

Better Demand Prediction

Advanced systems look at past sales to predict future needs.

According to McKinsey research, companies using AI-powered demand forecasting reduce forecasting errors by 20-50%.

This helps businesses keep the right amount of stock.

Planning for Seasons

The software spots seasonal trends and adjusts buying advice.

This prevents too much stock in slow times and ensures enough inventory during busy periods.

Manufacturers anticipate inventories shrinking by 1.6% in the coming 12 months, showing the need for better seasonal planning.

Less Waste

Accurate predictions reduce spoiled and outdated products.

The Food and Agriculture Organization states that 14% of food is lost between harvest and retail.

Proper inventory software can cut this waste by up to 30% for food businesses.

What Are the Benefits of Inventory Management Software?

Clearer Communication

Modern inventory management software improves supplier contact through auto data sharing.

Vendors get accurate forecasts and inventory updates. This helps them plan better and offer good prices.

Tracking Performance

The system watches supplier stats like delivery times, quality scores, and steady pricing.

This data helps businesses find the best partners and get better deals.

Bulk Buying Benefits

Steady demand forecasts allow smart bulk purchases. Businesses can get volume discounts while keeping proper inventory levels.

Happier Customers

Products Always Available

Good inventory control keeps products in stock across all sales channels. Inventory management software prevents empty shelves that upset customers and hurt your brand.

Managing Multiple Locations

The software shows stock across many warehouses and stores. Staff can quickly find products and fill orders from the closest inventory.

Faster Delivery

Smart inventory placement cuts shipping distances and delivery times. DHL research shows that optimized inventory placement can reduce shipping costs by 15-25% and cut delivery times by 2-3 days on average.

Making Smart Decisions with Data

Performance Reports

Detailed reporting gives insights into how inventory performs. Businesses can spot best sellers, slow items, and profit margins by type.

Planning Support

These systems create data that helps strategic business choices. Management can improve product mix, adjust prices, and plan growth based on accurate inventory facts.

Cost Analysis

Detailed cost tracking shows the real profit of each product. This helps businesses focus on high-profit items while cutting investment in less profitable inventory.

Growing with Your Business

Flexible Systems

Modern inventory systems adapt to changing business needs without full replacements. Companies can add new products, locations, and sales channels easily. The software is highly scalable, making it suitable for businesses of varying sizes and complexities.

More Efficient Staff

Automated processes reduce the need for extra admin staff as businesses grow.

Gartner research indicates that businesses using automated inventory systems can handle 40% more inventory volume with the same staff size.

System Connections

Premium inventory management software works with existing business systems like accounting, online stores, and customer management platforms.

These connections remove data gaps and improve overall efficiency.

Real-World Success Stories

Small Business Results

A clothing retailer with three stores reduced inventory costs by 22% within six months of using inventory software.

They cut stockouts by 85% and improved customer satisfaction scores by 18%.

Manufacturing Benefits

A mid-size manufacturer saved $2.3 million yearly after implementing automated inventory control.

They reduced excess inventory by 35% and improved production scheduling efficiency by 40%.

E-commerce Growth

An online retailer handling 10,000 orders monthly increased order accuracy to 99.2% using inventory software.

They cut fulfillment time from 48 hours to 18 hours while reducing shipping errors by 90%.

Measuring Your Return

Clear Benefits

Businesses usually see real improvements within three to six months:

- Inventory costs drop by 15-25%

- Admin time needs fall by 40-60%

- Empty shelf problems drop by 80-90%

- Overall inventory accuracy improves to 99%+

- Working capital tied up in inventory reduces by 20-35% (Deloitte study)

- Order fulfillment speed increases by 25-40% (Supply Chain Management Review)

Long-Term Value

The combined effect of these improvements creates big long-term value. A study by Boston Consulting Group shows businesses report yearly savings that often beat the software cost by 300-500%. The average ROI for inventory management software is 245% within the first two years.

Competitive Edge

Companies with efficient inventory management can offer better service, competitive prices, and faster delivery. These advantages lead to more market share and loyal customers.

Getting Started

Planning Needs

Good implementation needs careful planning and team support. Businesses should check current processes, find improvement chances, and set clear success measures.

Training and Help

Staff training ensures you get the most from your system. Most software companies offer full training programs and ongoing support services.

Managing Change

Moving from manual to automated processes needs good change management. Clear communication and gradual rollout help ensure smooth adoption.

Key Takeaways

Based on our analysis of industry data and real-world implementations, inventory management software delivers measurable benefits:

- Cost Reduction: 15-25% decrease in inventory carrying costs

- Time Savings: 40-60% reduction in administrative tasks

- Accuracy Improvement: 99%+ inventory accuracy vs 63% for manual systems

- ROI: Average 245% return on investment within two years

- Operational Efficiency: Handle 40% more inventory with same staff size

The choice to implement inventory management software represents a strategic investment in operational excellence that positions companies for sustainable growth in today’s competitive marketplace.